PRO CLEAN Electrostatic Oil Cleaner

Description

As an indigenous manufacturer of oil cleaning systems in India, Envair Electrodyne Limited offers a range of models serving a wide cross section of industry.

TECHNICAL SPECIFICATIONS

| MODEL | Specification (L X W X H) in mm |

Weight (Kg) |

PUMP Flow (Lit / Min) |

Water Contents Allowed |

| KEOC-2O C | 650 X 510 X 900 | 70 | 3 LPM | Below 500 ppm |

| KEOC-25 | 860 X 530 X 900 | 90 | 8-10 LPM | Below 500 ppm |

| KEOC -55 | 900 X 670 X 100 | 110 | 8-10 LPM | Below 500 ppm |

| KEOC-110 | 1040 X 670 X 910 | 150 | 8-10 LPM | Below 500 ppm |

| KEOC-110 DH | 1620 x 716 x950 | 400 | 8-10 LPM | Below 1500 ppm |

| FDU-35 | 1165 X 530 X 1300 | 205 | 8-10 LPM | Up to 3 % of Max |

| KEOC 55 PF | 1480 X 670 X 910 | 150 | 8-10 LPM | Below 750 ppm |

| KEOC 110 PF | 1620 x 716 x 915 | 200 | 8-10 LPM | Below 750 ppm |

KEOC unit also can be supplied with following options

a) Electronic controller

b) I/P supply 3 Ph N & E

c) Higher Flow Rate

d) Flow meter

The Superior Cleaning Method

Conventional methods of oil purification, viz: filtration, centrifuge, and straining, are incapable of adequately cleaning oil, as they remove particles only above 5 microns in size. These remaining small size particles cause high contamination and therefore require regular changing of oil.

Air breathers and cylinders effectively act as gates of entry to dust particles, which being only 2 microns in size, escape conventional oil purification methods. The Electrostatic cleaning represents a far superior and the most effective method of purifying hydraulic oil contamination caused by dust, abrasive metallic particles, oxidation sludge, and fine water. Oil cleaned by this new method meets NAS (National Aerospace Standards 1638) class 4/5 under standard test condition.

Scope of Application for Hydraulic Oil

SERVO SYSTEM 22,32,46,121,57,68,100,150,176

HLP – 22,32,46,68

HYDROL – 15,22,32,46,68,100,150

ENKLO – N-68, 68

BHARAT HYDROL HLP – 32.46.68

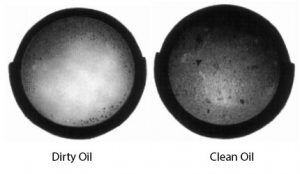

Microscopic Projection Of Oil Patch

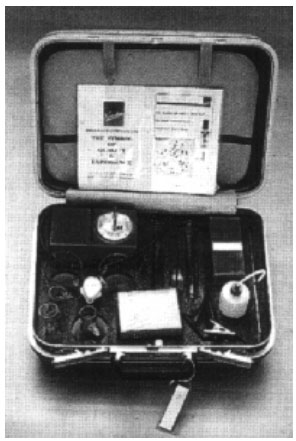

Oil Particle Patch Test Kit

This kit enables the determination of the oil cleanliness level before and after its filtration. The contamination level can be clearly seen from the colour of the oil patch created on a

submicronic membrane produced by-passing the oil through the membrane.

NAS 1638 Contaminants Specifications (Per 100 Ml)

| Class Of Oil | 00 | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| No. & Size of Contaminants (in microns) | 5-15 | 125 | 250 | 500 | 1,000 | 2,000 | 4,000 | 8,000 | 16,000 | 32,000 | 64,000 | 128,000 | 256,000 | 512,000 | 1,024,000 |

| 15-25 | 22 | 44 | 44 | 178 | 356 | 712 | 1,425 | 2,850 | 5,700 | 11,400 | 22,800 | 45,600 | 91,200 | 182,400 | |

| 25-50 | 4 | 8 | 8 | 32 | 63 | 126 | 253 | 506 | 1,012 | 2,025 | 4,050 | 8,100 | 16,200 | 32,400 | |

| 50-100 | 1 | 2 | 2 | 6 | 11 | 22 | 45 | 90 | 180 | 360 | 720 | 1,140 | 2,880 | 5,760 | |

| Above 100 | 0 | 0 | 0 | 1 | 2 | 4 | 8 | 16 | 32 | 64 | 128 | 256 | 512 | 1,024 | |

| For Missile | For NC M/C | New Oil | |||||||||||||